In the iron and steel industry, the coking process is mainly based on coal as a raw material to be refined, and coal, when combined with oxygen, produces a lot of wastewater with chemical substances, as well as some organic oils and sulphides and other pollutants, which, if discharged untreated or without proper treatment, can cause serious pollution of water sources. There are a large number of macromolecular organic compounds in wastewater that are difficult to treat, and these organic compounds combine with compounds such as carbon and phosphorus to form new oxides, making the treatment of coking wastewater more difficult and toxic than general wastewater.

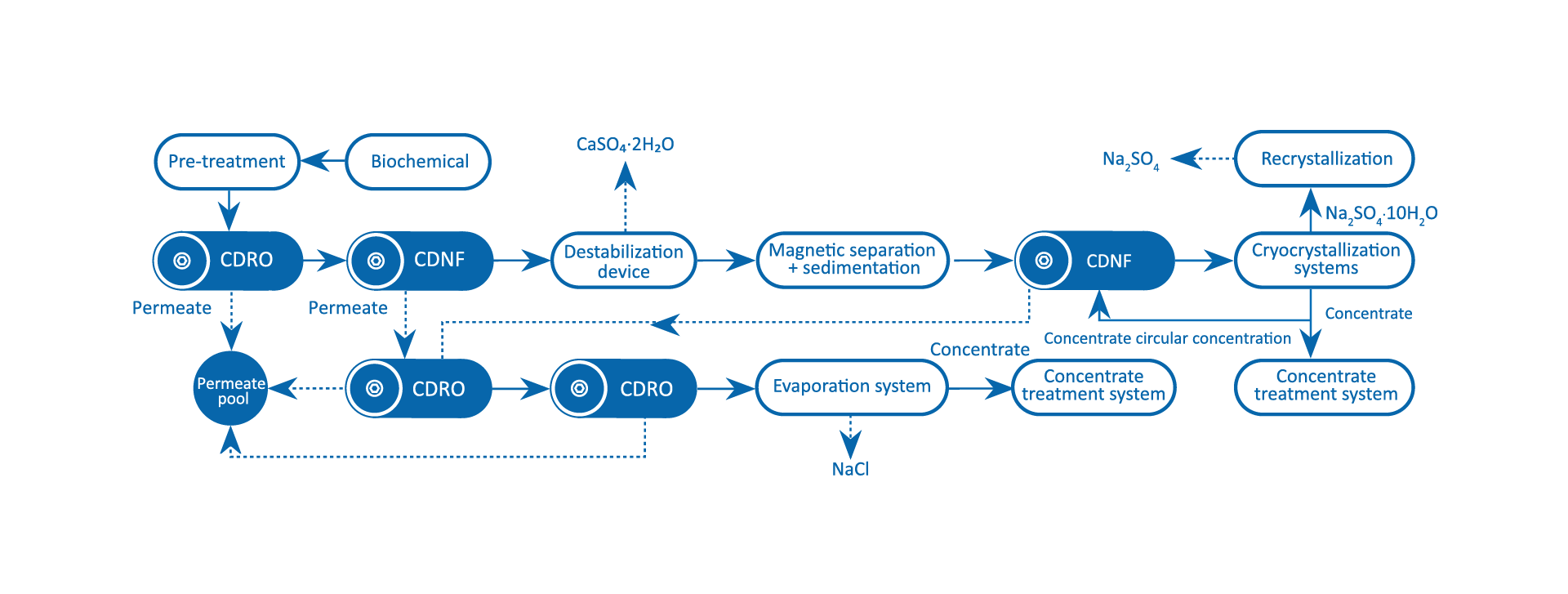

NF coupled with destabilization system, NF coupled with cryocrystallisation;

Resistant to high COD, high hardness, high TDS and other complex water quality;

NF Desalination synchronized with COD concentration, reduce through mother liquor;

Compared with UF+RO process, the chemicals reduce by 50%, and the overall operation cost reduces by 20%~30%.

Anhui linhuan coking wastewater treatment project 2400 m³/d (Phase I) 5760 m³/d (Phase II)

Sinopec chunfeng oilfield high temperature extraction water treatment project 10000 m³/d

Shandong dongyue organosilicon production wastewater treatment project 2400 m³/d (Phase I) 2400 m³/d (Phase II)