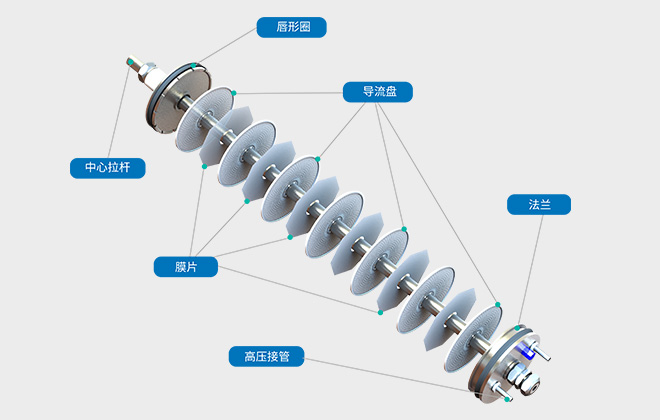

DTRO Module Series

The DT membrane module adopts a special open flow channel design, which consists of membrane cushion, disc plate, tie rod and housing. Raw water flows from the bottom up through the gap between housing and disc plate, and then enters disc plate through upper flange. Under pressure, water molecules pass through membrane cushion and flow out along the gap between tie rod and disc plate to form permeate.

Principle of operation and advantages

High recovery rate——Single module maximum recovery rate reachs 45%.

Simple membrane replacement——Membranes are individually replaceable, low maintenance costs.

Anti fouling and scaling——The convex design on the disc creates turbulence in the water, and the wide flow channel design with 1.2mm makes the product resistant to fouling and scaling.

Long service life——The service life of spiral wound module in a given scenario is up to 6 months, while the service life of NEWA module is 3-5 years.

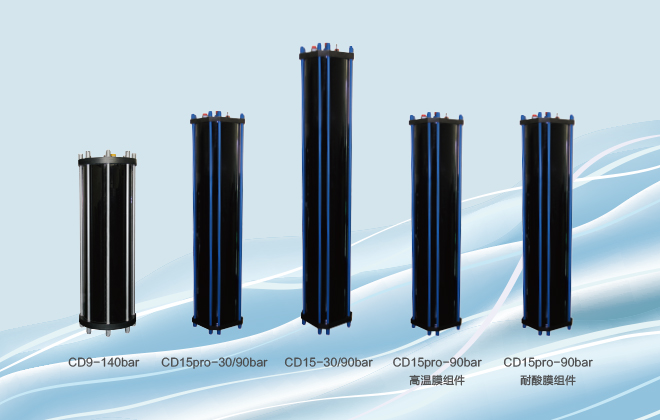

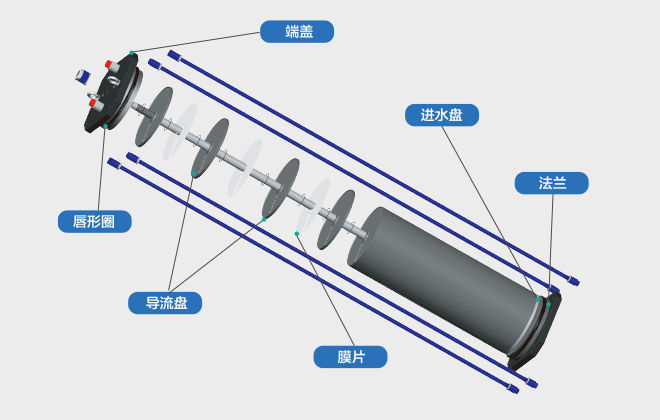

CDRO Module Series

The CD membrane module adopts a special open flow channel design, which consists of membrane cushion, disc plate, permeate anchor and housing. Raw water flows from the top down through the gap between housing and disc plate, and then enters disc plate through bottom water distribution plate it rises along the disc and membrane in a helicoidally pattern. Under pressure, water molecules pass through membrane cushion and flow out along the gap between permeate anchor and disc plate to form permeate.

Principle of operation and advantages

Wider flow channel——Wide flow channel design with 1.8/2.5mm makes the product resistant to fouling and scaling.

Linear convex layout——Excellent self-cleaning effect; reduces fouling and concentration polarization.

Coin- notch design——Reduced pressure loss, average pressure drop 2-4 BAR(30-60psi).

Manufacturing - Fully Automated Production Line

Relying on the Industry 4.0 manufacturing concept, NEWA has independently developed a fully automated production line for flat membranes to achieve large-scale and standardized production of membrane modules.

Sufficient production capacity: The production line has large capacity and high efficiency, and the whole process is assembled by smart robots, which can achieve 1,000 pcs/day to meet the demand of large-scale emergency projects.

Product exemption: the production line adopts advanced 4.0 technologies, robot assembly, visual inspection, product qualification rate of more than 99.99%, stable and reliable quality, to achieve product inspection-free

Dry membrane: Dry module delivered and the performance of the raw material is completely consistent with the long service life of the membrane module, storage longer, and at the same time to avoid the wet membrane growing bacteria and freezing, greatly facilitating the engineering application.

Smart management: the entire production process is monitored by data, realizing product quality process monitoring and problem traceability.

Price advantage: product standardization, large-scale production, significantly reduces the cost of membrane module production; improve the economy of various projects to choose a flat membrane process.